Hafis on Summary of ASME BPVC Section VIII Div 1 Part 4. Usually deep metric learning is often utilized to optimize distance loss to provide more discriminative features in image classification 24.

Cold Welding Vs Tig Welding Copper Welding Welding Equipment Welding Machine

This is the most unwanted defect of all the other welding defects.

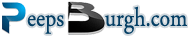

Tig welding defects images. Welding cracks can be present at the surface inside of the weld material or at the heat affected zones. Crack can also appear at different temperatures. The width of the bead should be consistent and have an attractive face surface profile.

I am a Mechanical Engineer with more than ten years of work experience in the field of welding and NDT. An ideal weld or good weld should be such that adequate fusion exists between the filler metal and edge preparation together with good penetration. In TIG welding autogenous techniques or stopping the welding wire entering the weld pool before extinquishing the welding arc will effect crater formation and may promote the pipe imperfection.

External Welding Defects. Gas tungsten arc welding GTAW also known as tungsten inert gas TIG welding is an arc welding process that uses a non-consumable tungsten electrode to produce the weldThe weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas argon or heliumA filler metal is normally used though some welds known as autogenous welds or. Ad China Tig Welding Machines.

Parveen kumar on Welding Defects. DEFECT ANALYSIS OF ORBITAL TIG WELDING SASIKUMAR NATARAJAN 1 2. It is a suitable time to explore how to use the TIG welder to weld rusty steel.

Extinquishing the welding arc will result in the rapid solidification of the weld pool. Trusted China Suppliers Verified by SGS. TIG Welding photo Previous.

Defect Analysis Of Orbital Tig Welding 1. Removing a root pass by grinding 1. You May Also Like.

Not possible for the welds to be completely sound Improper welding parameters wrong welding procedures introduce defects in the weld metal and HAZ Defects impair the strength of weld joints A defective weldment fails under service conditions causes damage to property loss of. The welding torch in most cases the TIG-welding process is used travels around the tubes to be joined guided by a mechanical system. TIG Welding GTAW Electrodes.

TIG welding is preferred by welding professionals to avoid the common problem of the formation of rust on the weld site. Trusted China Suppliers Verified by SGS. Furthermore an advanced deep learning model Resnet was applied to extract the image feature of different welding defects deeply and implement classification for various welding image.

Ad China Tig Welding Machines. The edges of the weld bead should have a smooth transition into the base metal without undercut a defect that appears as a groove in the parent material. The various types of external defects with their causes and remedies are listed below.

The presence or absence of defects in weld joints. Mechanical Vibrations Welding Welding Defects Tungsten-Inert-Gas welding TIG Discontinuities detection in welded joints based on inverse surface thresholding Automated detection of welding defects in radiographic images becomes nontrivial when uneven illumination contrast and noise are present. A good-looking weld is clean and is the same color as the base metal both inside and out-.

TIG welding is more modern arc welding which includes proper use of the non-consumable tungsten electrode to fill as well as fuse metals. Welding a root pass too wide can also cause the bead to sag overhead position. INTRODUCTION OF ORBITAL TIG WELDING Orbital welding is the first choice for the joining of tubes and pipes.

Cause for Insufficient Fill at the Root Some liquids like water or molten steel try to cover as much surface area of whatever they are in contact with as possible. Welding defects are generated in a welding job due to the faulty or poor technique used by the inexperienced or unskilled welder or due to fundamental difficulties in the welding operation.

Effect Of Heat Input And Filler Metals On Weld Strength Of Gas Tungsten Arc Welding Of Aisi 316 Weldments

Welding Projects Welding Welding Art

Welding Table Welding Projects Welding Training

Electrochemical Weld Cleaning The Fastest And Safest Way To Clean Stainless Steel Welds Cougartron

First Try At Aluminum Tig Welding With The Eastwood Tig200 Metal Projects Welding Tools Tig Welding

First Go At 6013 Welding Welders Machinist

Pin By Emmanuel2014 On My Shop ورشتي Welding And Fabrication Welding Projects Welding Table

Drawing And Welding Symbol Interpretation Welding Class Welding Table Welding Projects Welding

Tig Welding Machine Black Weld Bead Tungsten Point Processors Buy Tig Welding Machine Product On Alibaba Com

Types Of Welds And Welding Symbols Welding Productdesign Design Designengineering Mechanicalscience Mechanicalengineering Science Ma Gelassenheit

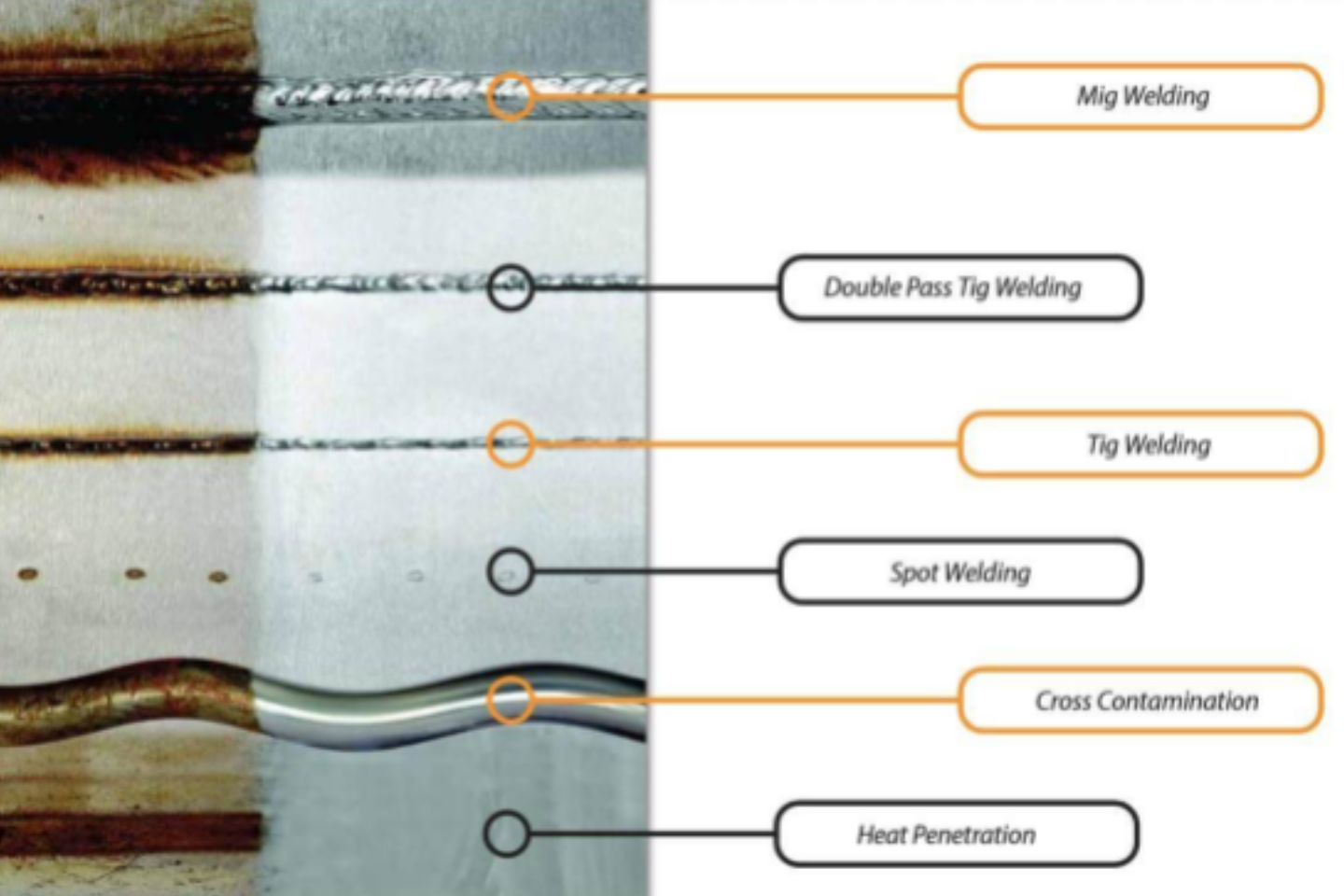

Applied Sciences Free Full Text Application Of Pulsed Laser Tig Hybrid Heat Source In Root Welding Of Thick Plate Titanium Alloys Html

Weld Positions Joints All About Mechanical Engineering Welding Table Welding Welding Projects

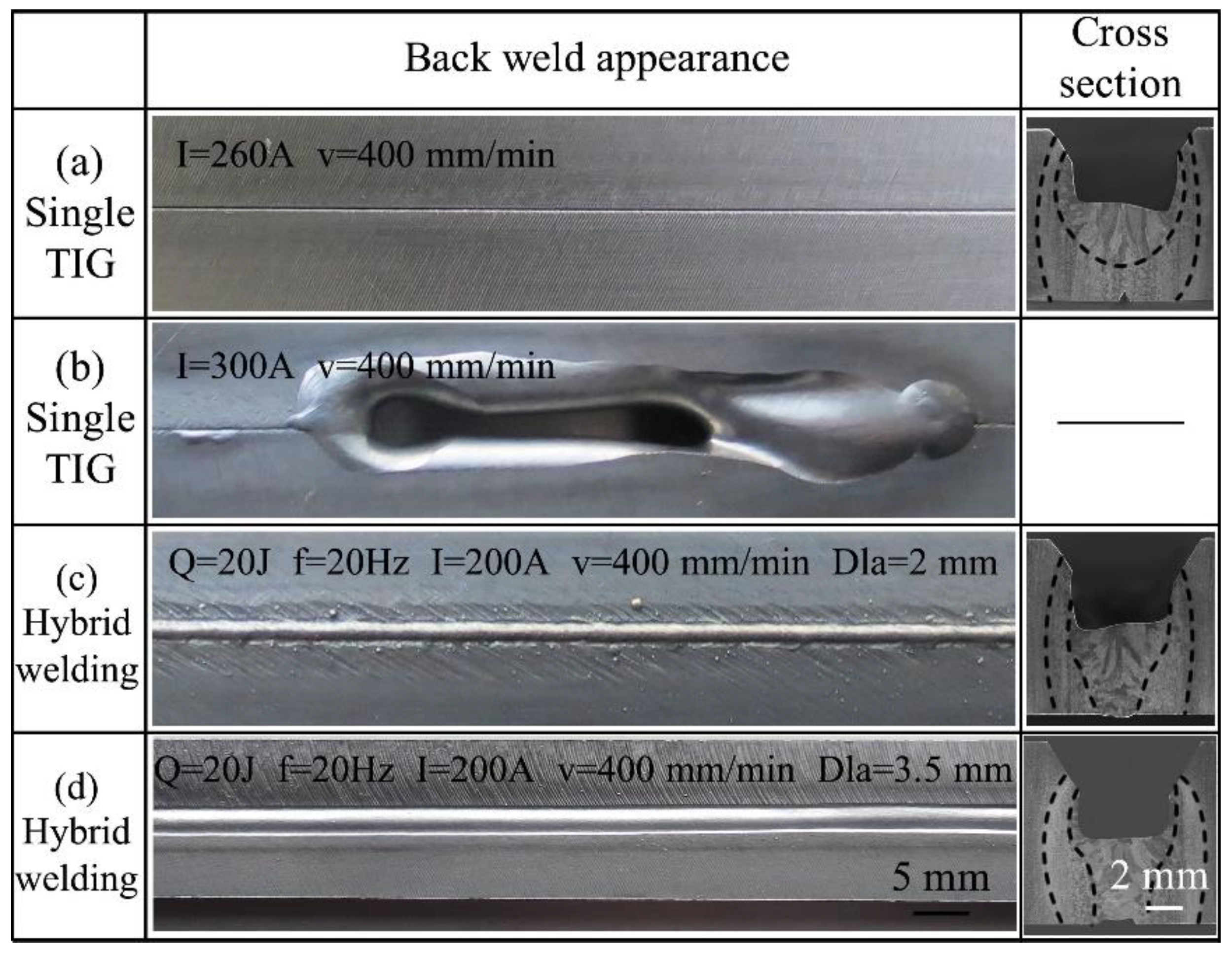

Metals Free Full Text Characteristics Of Welding And Arc Pressure In The Plasma Tig Coupled Arc Welding Process Html